Spotlight On The Ipcote Range

Summary. Indestructible Paint are experts in high temperature coatings and high corrosion resistant coatings. Our Ipcote range, originally developed for Rolls-Royce Aero Engines, offers protection in challenging environments such as aero engines and marine settings. We also provide chrome-free alternatives for safer coatings. Explore our Ipcote range for diverse applications.

High Corrosion & High Temperature Resistance

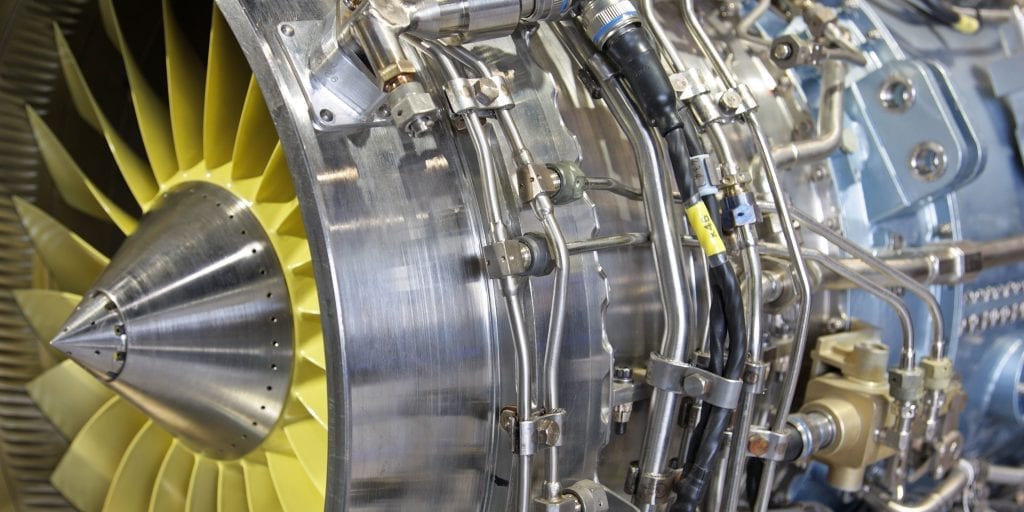

Indestructible Paint’s Ipcote range of sacrificial aluminium base coats and seal coats are high corrosion resistant and high temperature coatings. They are designed for use in many challenging environments. For instance, aero engine, aircraft landing gear, power generation and marine situations.

We developed and refined the range over several years. Initially, we introduced it at the request of Rolls-Royce Aero Engines to use on compressor blades and allied engine parts. Therefore, being a commercially available alternative to a proprietary range of imported US products. Subsequently, many additional aero engine and industrial gas turbine manufacturers have adopted our Ipcote coating range. We also introduced it as a cadmium replacement on undercarriages and fasteners.

Chrome Free Alternatives

Initially the range was purely based on inorganic technology, which by its very nature contained both trivalent and hexavalent chrome. Recent introduction of environmental and safety legislation has highlighted the use of chrome containing products. The levels of hexavalent chrome in most of the products are minimal, and in most cases below all current environmental limits. However, there are ongoing developments to remove all chrome compounds. We offer a single-component, solvent-containing chrome-free coating based on organic chemistry, tested to Rolls Royce MSRR 9253 standards. In addition, we are testing with clients, a chrome free inorganic base coat and sealcoat.

We developed CFIPAL as a chrome-free version of our diffused aluminide coating (IP1041) to protect gas turbine hot section parts up to 1000°C. Often used on nickel-based turbine alloys, this coating provides high-temperature oxidation-resistant silicon-aluminide protection for industrial and aero-gas turbine components.

THE IPCOTE RANGE OF SACRIFICIAL ALUMINIUM BASE AND SEAL COATS Includes:

IP9183-R1 High Heat Resistant Sacrificial Aluminium Coating

MSRR 9140, OMAT 7/46B, PCS2550, ITP SM-903, LB 598, GEA50TF1 Class E, Snecma – DMR74–052

Sacrificial Aluminium Coating that is part of a range of corrosion resistant coatings designed for use in challenging environments such as aero engine, power generation and marine situations. Spray applied, Ipcote is used on turbine blades, rotors, shafts and landing gear. Consequently, protecting components from salt laden atmospheres, high temperature oxidation, chemicals and abrasives.

IP9183-R1 TDS

IP9184 Ipseal High Temperature Inorganic Seal

MSRR 9140, OMAT 7/168B/G, LB598, ITP SMM-903, PCS 2550, GEA50TF196 Class F

This is an inorganic protective coating for use as a barrier on Ipcote IP9183-R1, IP9253, PL219, Ipthin IP9356.

All of the Ipcote coatings are conductive, sacrificial coatings and inherently porous. Ipseal seals this porosity without detracting from their sacrificial properties. It also creates an electrically non-conductive barrier coat.

IP9184 – GREEN TDS

IP9184 – KHAKI TDS

IP9442 Smoothcote – Smooth Surface Finish Sacrificial Aluminium Coating

LB598, CPW88

Sacrificial aluminium coating providing a very smooth surface finish, necessary to reduce friction and to enhance efficiency in aero engines. IP9442 has a typical sprayed surface finish of approximately 20 micro inches thus presenting little resistance to air flow or roughness. Therefore, resulting in low dirt and carbon deposit pick up. When polished, finishes of less than 10 micro inches have been achieved.

IP9442 TDS

IP9444 Smoothseal

MSRR 3010, OMAT 7/262, NATO STOCK 8030-99-371090, RR Code 137616, ITP SMM-903/1, Safran Landing Systems (Messier-Bugatti-Dowty) PCS 2550, Messier Dowty PS637 and PS639, Safran Aero Engines (Snecma) DMR 74-052 (Application to DMP16-049) GE – A50TF1, Class E

Smoothseal is an inorganic protective coating used as a barrier on Ipcote IP9183-R1, IP9253, PL219, Ipthin IP9356. Smoothseal cures to provide an ultra-smooth finish to improve dirt shedding and air flow properties. Furthermore, all of the Ipcote coatings are conductive, sacrificial coatings and inherently porous. Smoothseal seals this porosity without detracting from their sacrificial properties. It also creates an electrically non-conductive barrier coat.

IP9444 TDS

IP9447-R1 Green Smoothseal

A light green, inorganic protective coating used as a barrier normally on Smoothcote IP9442 to give an ultra-smooth finish. Smoothseal, seals any porosity within the sacrificial aluminium coatings that it covers and creates an electrically non-conductive barrier coat.

IP1041 IPAL Diffusion Coating

MSRR1041, OMAT 7/129A

Ipal IP1041 diffused aluminide coating is designed as a protective coating for gas turbine hot section parts at temperatures up to 1000ºC. Ipal IP1041 is used for sulphidation protection in industrial and marine gas turbines. Moreover, it is often for use on nickel based turbine alloy materials the coating imparts a high temperature oxidation resistant aluminide coating for turbine components in all areas of industrial and aero gas turbine use.

IP1041 TDS

IP9356 IPThin Thin Film High Heat Resistant Sacrificial Aluminium Coating

MSRR 9356, ITP SMM-919, OMAT 7/167A, NATO STOCK 8030998646844

Sacrificial Aluminium Coating IP9356 is used on turbine blades, rotors, shafts and landing gear. Therefore, protecting components from salt laden atmospheres, high temperature oxidation, chemicals and abrasives.

IP9356 TDS

IP9064-KHAKI 2 Pack Epoxy Khaki Sealcoat

DTD 5555; 5567, MSRR 9064, BSX 32, BSX 33 (Type A & B), HCP 355 (AEC’s Paint Procedure), Def Stan 80-161

A 2 part air drying epoxy finish for use over IP9183-R1 Ipcote. This coating is based on the binder system used to meet the specifications shown below. Moreover, the cured coating is resistant to abrasion, corrosion and most aircraft operating fluids and chemical.

IP9064-KHAKI TDS

Ipcote Roller

The Ipcote Roller is designed for use with one litre and five litre screw top Ipcote plastic bottles. Suitable for mixing non-flammable products only, such as the Ipcote Range – supplied by Indestructible Paint Limited, in the manufacturer’s original containers

The machine runs at fixed speed and is fitted with an interlocked rear hinged lid and an overload protected starter. It is fitted with a cooling fan, drawing fresh air in through the stainless steel cover and discharging through ventilation holes in the left hand side of the machine when viewed from the front.

Ipcote Roller TDS

Furthermore, if you found this blog useful, why not take a look at a previous one: Spotlight on The Rockhard Range