RWIP120 Epoxy Coating and Maintenance System for the Rail Industry

Summary. Indestructible Paints Ltd, a UK specialist, has launched the RWIP120 epoxy coating for rail and high-performance epoxy coating applications. Utilising advanced polymer technology, this product offers excellent corrosion protection, extending the lifespan of rail assets. Suitable for various substrates, its benefits include resistance to heat and chemicals.

Indestructible Paints Ltd established themselves as a UK manufacturer long ago. We are specialists in high-performance protective coating systems. Therefore, we supply industries such as rail, aerospace and land defence industries. Utilising the latest polymer technology. Indestructible Paint Ltd have been adopting this technology for use, within the passenger and freight rail sectors.

For instance, underground vehicles, offering excellent corrosion protection in aggressive operating conditions. Consequently, extending the operating life for its customers assets.

Indestructible RWIP120: High-Performance Protective Coating in Focus

The first fully compliant product from Indestructible Paint Ltd for use on under-frame components is RWIP120. This high-performance epoxy coating is a high solid solvent-based product.

Furthermore, you can apply it directly to the substrate as a single coat or use it in a 2-coat application with a primer and finish. You can also overcoat it with itself or other finishes from Indestructible Paint, including epoxy and polyurethanes.

Indestructible Paint developed RWIP120 as part of their family of coatings. They manufacture it from a high-grade 2-part epoxy system, which they initially procured for aerospace applications. However, Indestructible have subsequently taken this resin binder system to manufacture a range of low VOC coatings. Furthermore, these are intended for rail, industrial, transport and architectural applications. These coatings are ideally suited for use on under-frame components. For instance, bogies, wheel-sets, motors, fluid or air receivers, control enclosures, support structures, etc.

The composition of the epoxy as well as its chemical bonding properties, allows the use, on a range of substrates. This includes, ferrous and non-ferrous metallics, GRP mouldings and a wide range of composites. Additionally, the cured coating is a tough chemically resilient finish. It has been tested against a variety of corporate and national standards. For example, CR/PE0102 and EN45545-2 for Fire Smoke and Toxicity.

Rail Applications Of The RWIP120 High Performance Epoxy Coating

The Benefits of RWIP120 Epoxy Coating

- 2 component high solids aerospace grade epoxy coating.

- Proven long term corrosion protection.

- Excellent fire performance properties.

- Good resistance to abrasion and mechanical damage.

- Applied directly to range of substrates. For instance, Steel, Stainless Steel, Aluminium, Galv, GRP and Composites.

- Outstanding resistance to immersion in aqueous solutions and a wide range of chemicals.

- Excellent resistant to dry heat-100 hours at 180 deg.C. and hot oil immersion.

- Single coat system applied direct to substrate at 80 – 120 microns dft. (finish semi-gloss).

- 2-coat system, primer matt at 40 – 60 microns dft, finish coat at 40 – 60 microns dft (finish matt to full gloss).

- Available in a range of BS. and RAL colours and gloss levels from matt to full gloss.

After 7 days air curing or force curing for 30 minutes at 125°C, the coating will pass:

– Heat resistance: 48 hours at 204°C (400°F)

– Heat resistance: 100 hours at 180°C (356°F)

– Hot oil immersion: 8 hours in ASTM Fluid 101 (ASTM D 471) at 177°C (350°F)

showing no peeling / softening

– Hot lube oil immersion: 100 hours at 150°C (302°F)

– Fuel resistance: immersion in ASTM ref fuel B for 4 hours at room temperature without peeling / softening

– Fuel resistance: room temperature immersion 100 hours

– Corrosion resistance: after exposure to heat (48 hours at 400°F) cross scratched X withstands

350 hours salt spray ASTM B117

– Heat Salt Fog Resistant to 10 cycles: each cycle, 4 hours at 250°C (300°F) then 20 hours salt fog

– Resistant to temperatures down to -50°C

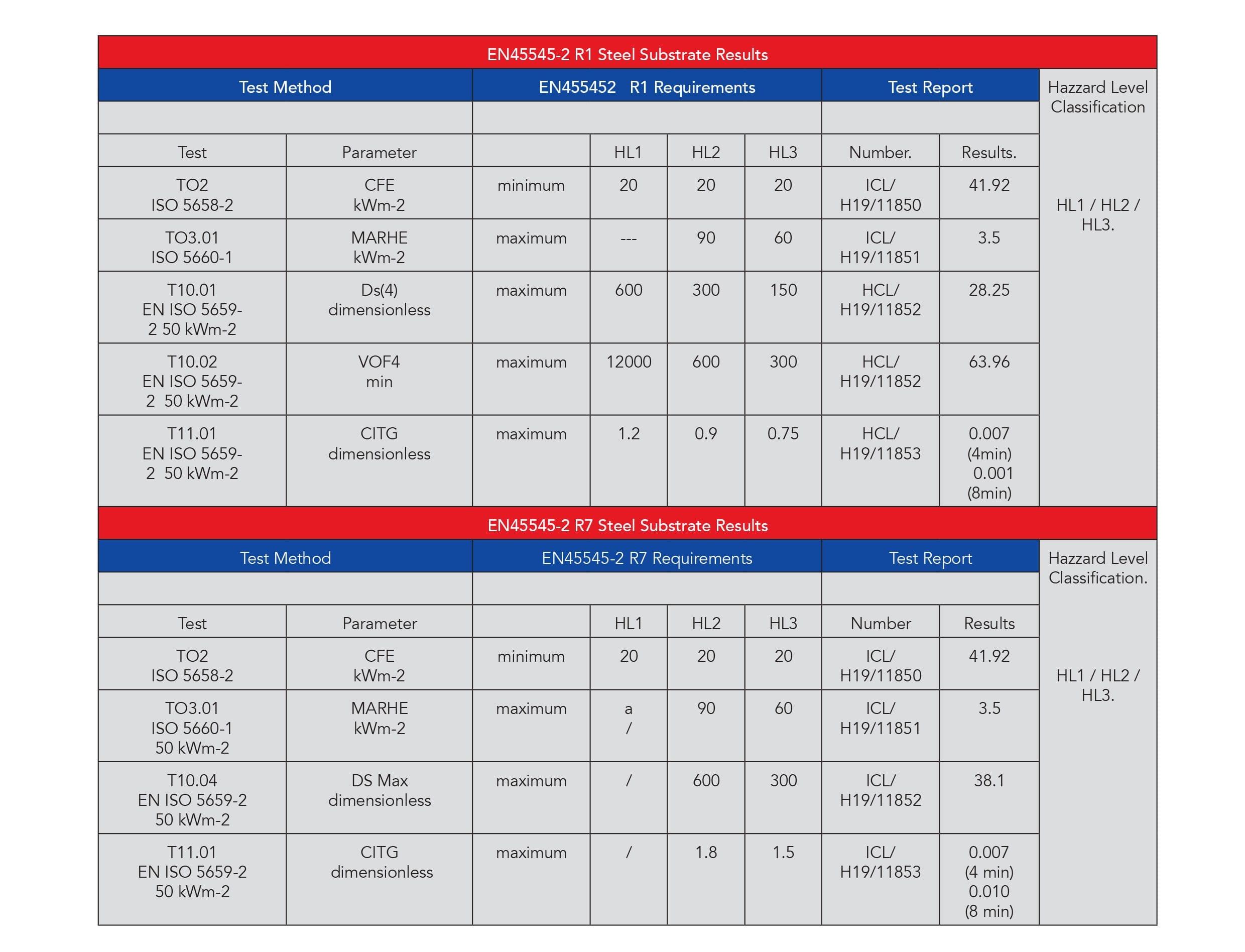

Test Results for RWIP120 Epoxy Coating

Before use, refer to Product Technical Data Sheeet and the Product Safety Data Sheet. Furthermore, to request a Safety Data Sheets please visit our website.

As a leading rail coatings supplier we can answer any enquiries regarding the RWIP120 epoxy coating. So please call us on: +44(0)121 702 2485. Alternatively, you can email us at sales@indestructible.co.uk.

If you found this blog useful, why not take a look at: High Build Epoxy Primer and Finish Coat for the Rail Industry

View the RWIP120 Brochure