Spotlight on Rail Vehicle Coatings

Summary. Rail Vehicle Coatings, such as RWIP120 and RWIP3000, highlight Indestructible Paint’s expertise in engineered performance coatings. These robust epoxy systems, tailored for the rail industry, ensure optimal protection, resilience, and aesthetic versatility for diverse rail components and environments.

Highly Versatile and Robust Epoxy Coating Systems with Huge Benefits for the Rail Industry.

Indestructible Paint is a leading manufacturer of engineered high-performance coating systems for a wide range of industries. In this blog, we are proud to introduce two of our most versatile and robust epoxy coating systems: the RWIP120 and the RWIP3000. The specific design of these coatings meet the unique challenges the rail vehicle industry faces. In addition, we have tested them to the highest standards.

RWIP120 Coating System

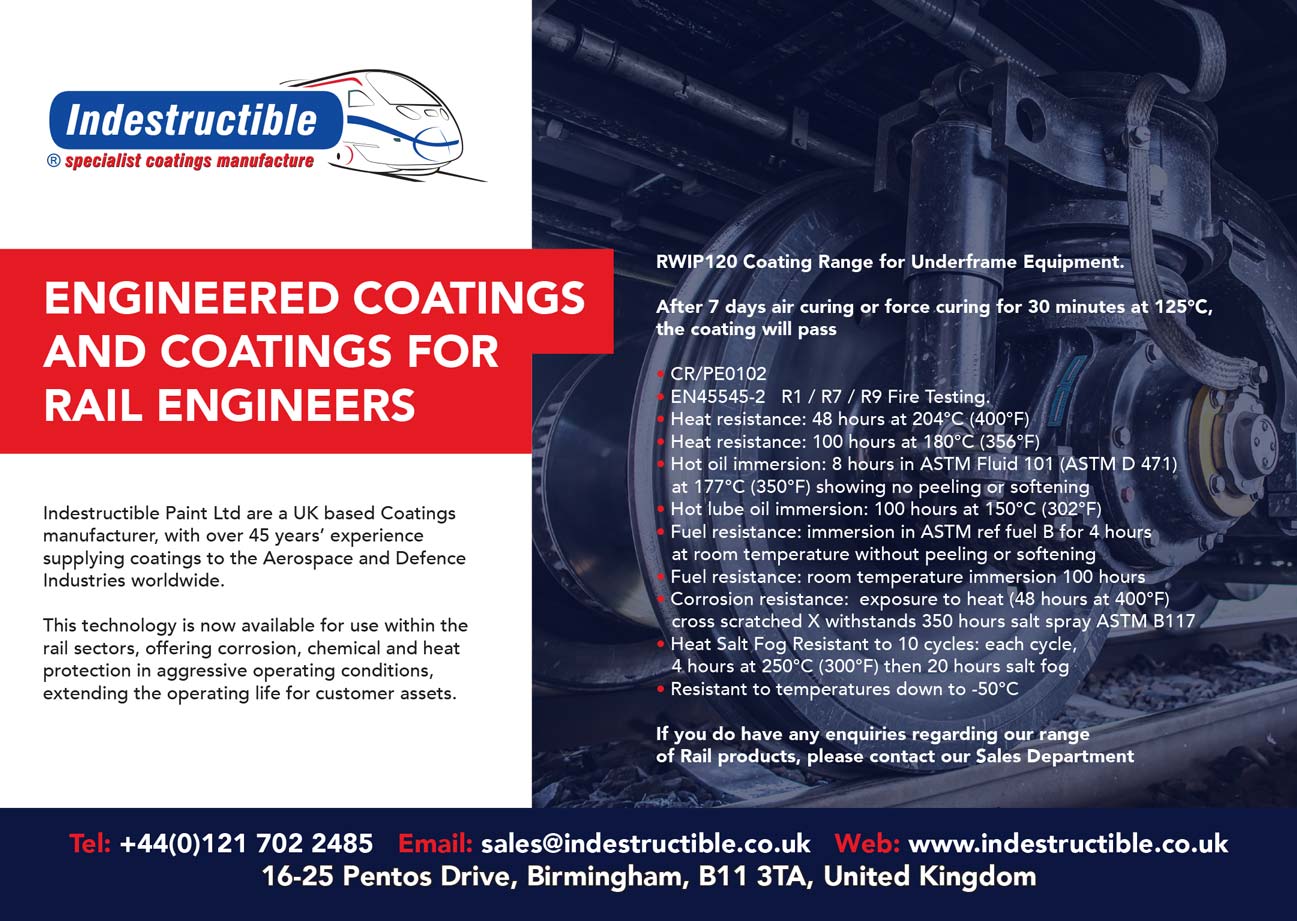

The first development is centred on the introduction RWIP120. This coating is a result of four decades of experience in coating technology in some of the most challenging global environments. Moreover, this RWIP120 coating is fully compliant with CR/PE0102 Repainting of Rail Vehicles specification. It offers a range of performance benefits and, significantly, is available as either a one or two coat system.

The system can often achieve under frame coating objectives using a single 120 micron primer/finish coating. This is particularly because there are no specific aesthetic considerations. While, in other areas, it can comprise a separate 60 micron primer with an additional 60 micron finish coat. Additionally, when appropriate, you can over-coat it with other Indestructible Paint finishes, epoxies, and polyurethanes.

Furthermore, we can meet customer needs by offering a choice of colours ranging from a matt to full gloss finish.

Performance Capability & Benefits of RWIP120

RWIP120 has been proven on a range of substrates, many of which are a common feature in the rail sector. These include steel, aluminium, galvanised and composite surfaces. All of which gain from the composition of the epoxy and its chemical bonding characteristics.

We have tested the cured coating, a tough chemically resilient finish, against a variety of corporate and national standards.

Indestructible Paint has developed the system as part of a family of coatings. It is based on high grade, two-part epoxy coatings that have a long and successful track record in the Aerospace and Land Defence sectors.

The performance capability of the RWIP120 range covers a long list of challenges faced by rail operators. From impact, chip and scratch resistance to the ability to withstand high temperatures and high humidity environments. Additionally, other key benefits to the rail industry include the proven resistance to abrasion, salt spray and wash plant operations.

RWIP3000 Intumescent Coating

The second development is RWIP3000, a thin film intumescent coating. When intumesced, the coating forms a barrier to protect the substrate from burning for a specific number of minutes. Dependant on thickness, and when used in conjunction with a heat absorbing primer, RWIP3000 is further suitable for hot areas typically found under a train, for example, around an exhaust area or motors.

Performance Capability of RWIP3000

RWIP3000 performs on a range of substrates, including metals, timber and composites. The coating is also suitable for both air-drying and forced-drying, and maintains excellent adhesion. This includes, most importantly for the rail sector, where high air movement is present.

RWIP3000 is normally applied as a primer/sealer intumescent coating, which can then be overcoated with a two-component epoxy or polyurethane topcoat. It can be applied either by spray or brush.

Testing of RWIP3000

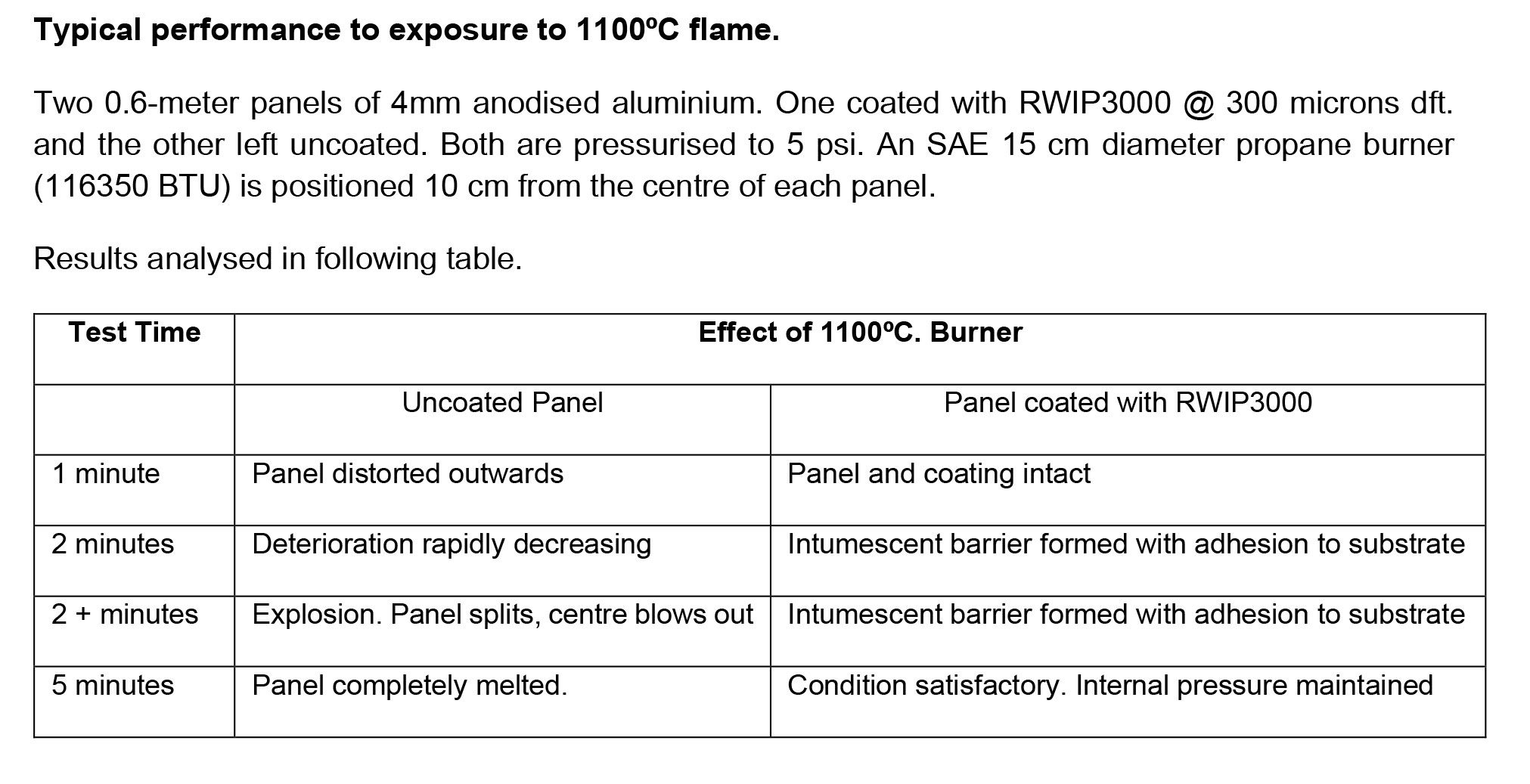

A clear demonstration of the performance capability of RWIP3000, is the specific testing operation (pictured above). Centred on exposure to an 1100 C flame, with the flame positioned 10cm from a 4mm anodised aluminium substrate, the panel condition remained satisfactory.

With internal pressure maintained, after a five-minute exposure period, by comparison, over the same period, a non-coated panel distorts and deteriorates before splitting, exploding and completely melting.

Similarly, RWIP3000 coating has been shown to maintain heat resistance when exposed to 180°C heat source for more than 100 hours.

Looking for engineered performance coatings for the rail industry?

Contact Us Today

At Indestructible Paint, we commit ourselves to providing our customers with high-quality engineered performance coatings that meet their specific needs. Our RWIP120 and RWIP3000 coatings have been specifically developed to meet the unique challenges faced by the rail vehicle industry.

Contact us today to find out how we can help you with your coating requirements.