Indestructible Paint’s Engine Coatings Benefit The Industrial Gas Turbine Industry

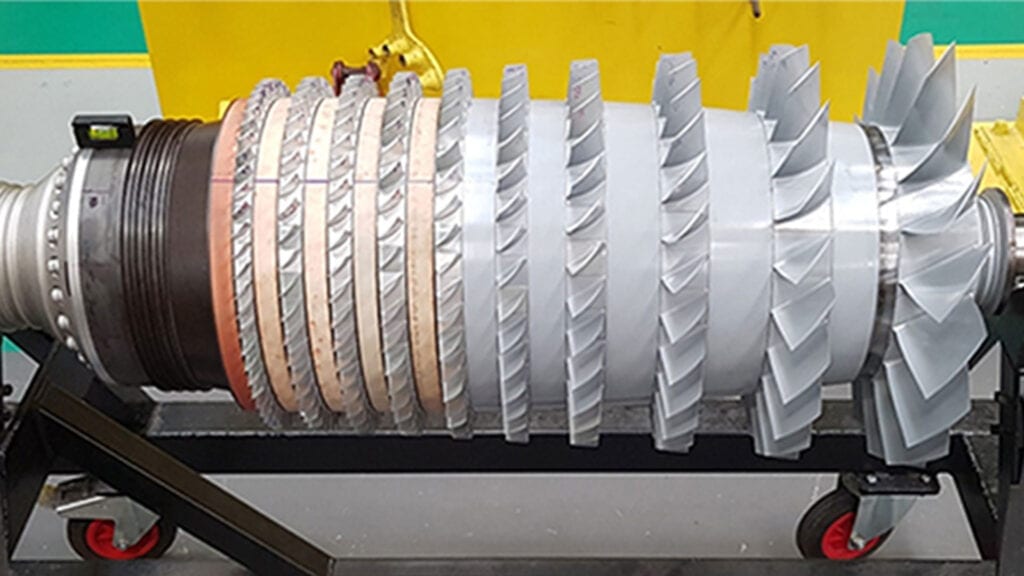

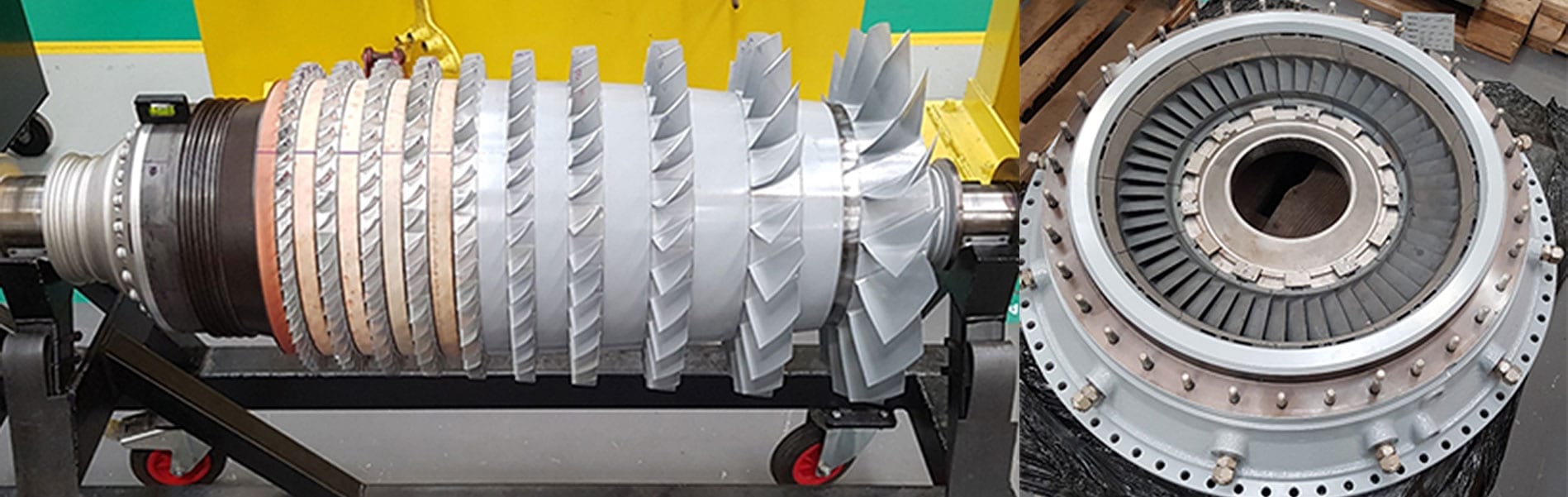

Indestructible Paint Ltd, is a leading high performance engine coating supplier in the UK. Over the last six years, we have been working closely providing engine coatings to Turbine Efficiency Ltd. They are an industrial gas turbine overhaul and repair specialists, based in Lincoln, UK. Together, we develop a variety of coatings for the overhaul of turbines to protect and enhance equipment performance.

Indestructible Paint work closely with Turbine Efficiency to gain a thorough understanding of the challenging environment. As well as the requirements of their gas turbine fleet. This is done by utilising and expanding our specialist technologies developed for the aero engine market. Moreover, we have served the engine market for over 40 years and have become their primary coating supplier.

Driving For Environmental Improvement

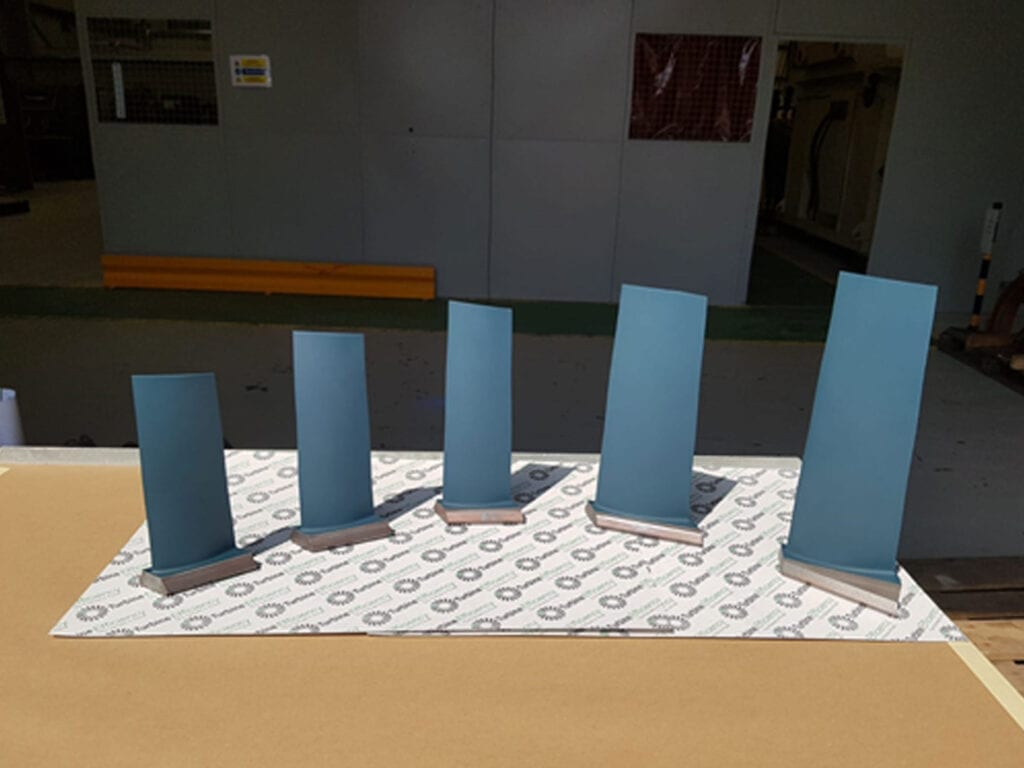

Furthermore, of particular importance is the development of chrome-free coatings. They underscore Turbine Efficiency’s drive towards environmental improvement, and our commitment to meeting REACH obligations. TELxPro, a proprietary coating designed just for Turbine Efficiency. It is an example of our ability to develop and supply coating solutions that meet the specific needs of niche market sectors; an approach our reputation is centred upon.

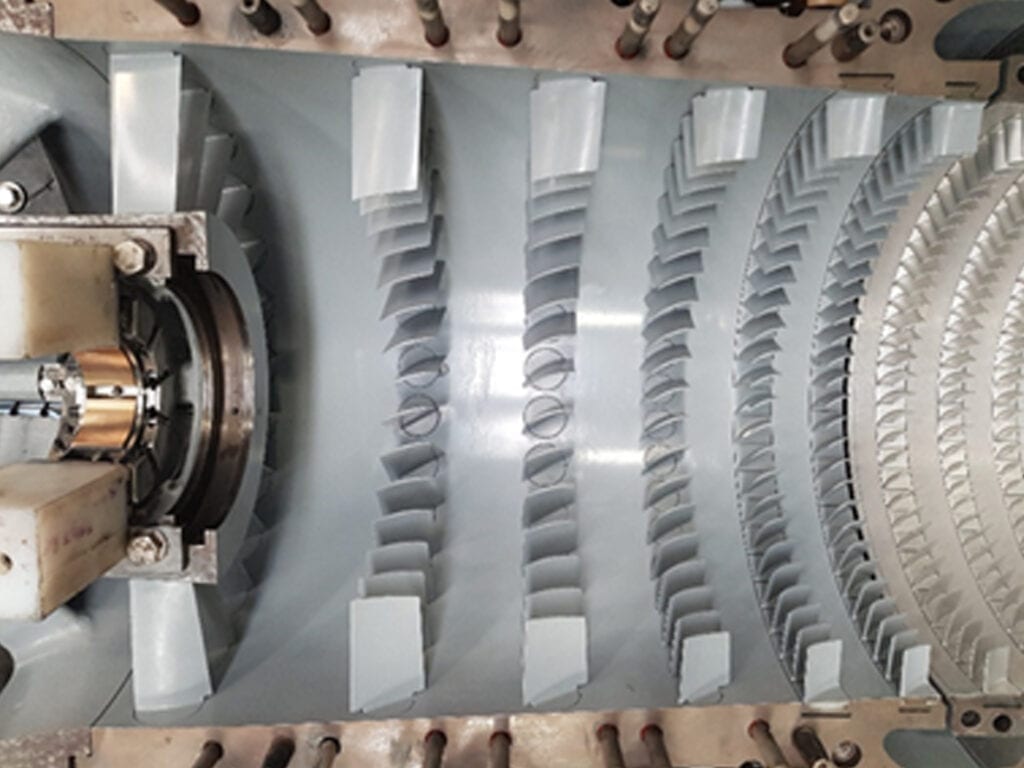

“The sealer coating not only provides an incredibly smooth coating, which is a significant improvement on previously used coatings, but is also very stable during the curing process. Ensuring the delivered condition of the components to our engine build are of the best quality and visual appearance that they can be,” says Paul Holder, Head of Coatings and Repair at Turbine Efficiency.

Alongside the cold section compressor coatings provided to Turbine Efficiency, IP1041 IPAL Diffusion Coating is in use for the hot section components. Ipal provides outstanding protection for gas turbine hot section parts at temperatures up to 1000ºC.

“It is a superior coating to others in this area of silicon modified diffusion aluminides not only in the application but for its performance during the engine lifecycle,” adds Paul Holder.

Heat Resistant Turbine Blade Coatings

Being erosion and corrosion resistant are also principal requirements for the overhaul of turbine blades. By utilising IP9183-R1 Ipcote High Heat Resistant Sacrificial Aluminium Coating alongside TELxPro Chrome Free Sealer, the life of the turbine blades is extended.

In addition, Turbine Efficiency make use of various other coatings from Indestructible Paints. For instance, this includes sealer coatings IP9184-Blue, IP9184-Khaki and IP9444 Smoothseal for larger frame engine components, again, for their unsurpassed erosion and corrosion properties.

All images courtesy of Turbine Efficiency Ltd.

Furthermore, to find out more about our power generation coatings by emailing sales@indestructible.co.uk today.