Sacrificial Aluminium Coatings For Aero Engines And Power Generation

Summary. Explore Indestructible Paint, a leading aluminium protective coating manufacturer, offering innovative solutions like the IP9183-R1 Ipcote and Ipseal IP9184, designed to robustly safeguard various metals in challenging, high-temperature environments, and enhance engine efficiency.

Looking for an aluminium protective coating? Indestructible Paint is one of the country’s leading manufacturers of high performance protective coatings including Sacrificial Aluminium Base-coats and Seal-coats.

Ipcote IP9183-R1 Base-Coat & Ipseal IP9184 Seal-Coats

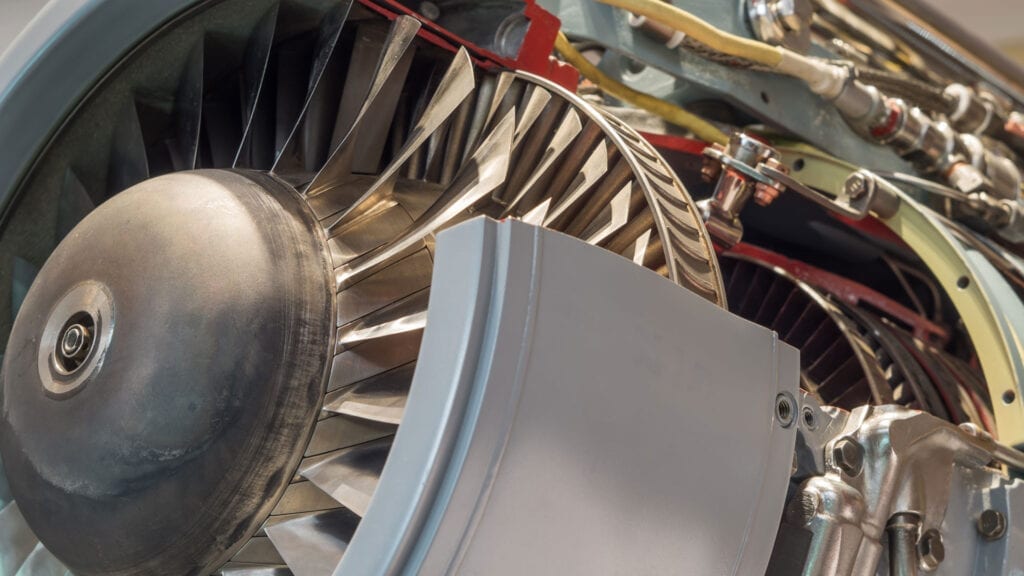

IP9183-R1 Ipcote Sacrificial Aluminium base-coat is part of a range of corrosion resistant coatings. They are designed for use in challenging environments. This includes aero engines and components, power generation turbines and marine engines. You apply Ipcote by conventional spray to use on compressor blades, rotors, shafts and landing gear. It provides protection from salt laden atmospheres, high temperature oxidation, chemicals and abrasives.

The coating provides corrosion and oxidation protection to iron, steel, heat treated stainless steel alloys, titanium and other metallic substrates at temperature of up to 700°C. IP9183-R1 Ipcote, can also be super or vibro polished. This will enhance flow of air in aircraft engines where smooth surfaces are essential to enhance energy efficiency. When vibro polished a Ra surface finish of ≤ 12 micro inches is readily achieved.

Improving Engine Efficiency

Ipseal IP9184 is an inorganic protective coating used as a barrier on Ipcote. It is available in green, khaki and blue to meet specific requirements.

Ipcote coatings are conductive, sacrificial coatings. However, they are porous. Ipseal seals this porosity without detracting from their other properties. It also creates an electrically non-conductive barrier coat. The use of Ipseal on top of these products results in a smoother, harder coating. This provides a barrier against carbon deposits, etc. Therefore extending the useful life of the base coat and providing a smoother finish. The finish enhances airflow characteristics and therefore engine efficiency.

Ipseal IP9184 is for use at temperatures up to 800⁰C (1400⁰F). This material is also a coating in its own right. It provides high-temperature resistance up to 800⁰C on such metals as nickel. It has shown a 70% reduction in Alpha Case corrosion on titanium at 650⁰C at 3-5 microns DFT.

Approvals from Aerospace and Power Generation Prime and Tier 1 Suppliers

Ipcote and Ipseal have multiple approvals from primes and tier 1 suppliers. Including GE, Roll-Royce, Pratt & Whitney, Safran Aircraft Engines, Safran Helicopter Engines, Safran Landing Systems, Siemens Power Generation, Airbus Helicopters.

NOTE: Ipcote and Ipseal products contain Chromium Trioxide: CAS No: 1333-82-0. Chrome free alternatives are under client evaluation.

Aluminium Protective Coating Manufacturers | Contact Us Today

If you would like to find out more about aluminium protective coating solutions, you can see the ipcote product range on our website. Or, call +44(0)121 702 2485 to speak to a member of our helpful and friendly sales team. You can also email us at sales@indestructible.co.uk .

If you have found this blog helpful, then you may wish to read our previous blog on Indestructible Paint’s Versatile Coating System Benefits the Rail Industry.